Shops for headlight restoration?

#1

Shops for headlight restoration?

I bought some headlight motors that came from a car that was being parted out. They both work, but they are showing their age and I would like them to be restored for extra assurance once I tackle replacing my already existing headlight motors.

I saw on a Corvette forum that someone had their headlight motors on their Stingray redone but they didn't bother naming the shop. Does anyone know any shops that can restore mine?

I also know a Corvette guy who would also like this information for his own Stingray.

Thanks guys.

I saw on a Corvette forum that someone had their headlight motors on their Stingray redone but they didn't bother naming the shop. Does anyone know any shops that can restore mine?

I also know a Corvette guy who would also like this information for his own Stingray.

Thanks guys.

Last edited by Redliner223; 03-26-12 at 01:05 PM.

#2

the only realy wear items are the bushings and you have to buy the whole rod to replace them

http://mazdatrix.com/n-6.htm

as for the motors themselves? any auto electric place that rebuilds alternators and starters should be able to rewind the coils in the motor.

http://mazdatrix.com/n-6.htm

as for the motors themselves? any auto electric place that rebuilds alternators and starters should be able to rewind the coils in the motor.

#3

You mean like this? You can do this yourself, a little disassembly, cleaning and painting. I've done 3-4 sets the last couple years. The only thing I used, out of the ordinary would be my blast cabinet and dropping some bits off at the plating shop.

#5

Joined: Feb 2006

Posts: 3,162

Likes: 1

From: London, Ontario, Canada

Look for a metal refinishing shop near you (google). They can plate, chrome, sandblast or polish most things you bring them. There's one here that always has a pile of caterpillar heavy equipment parts waiting to be refinished.

#6

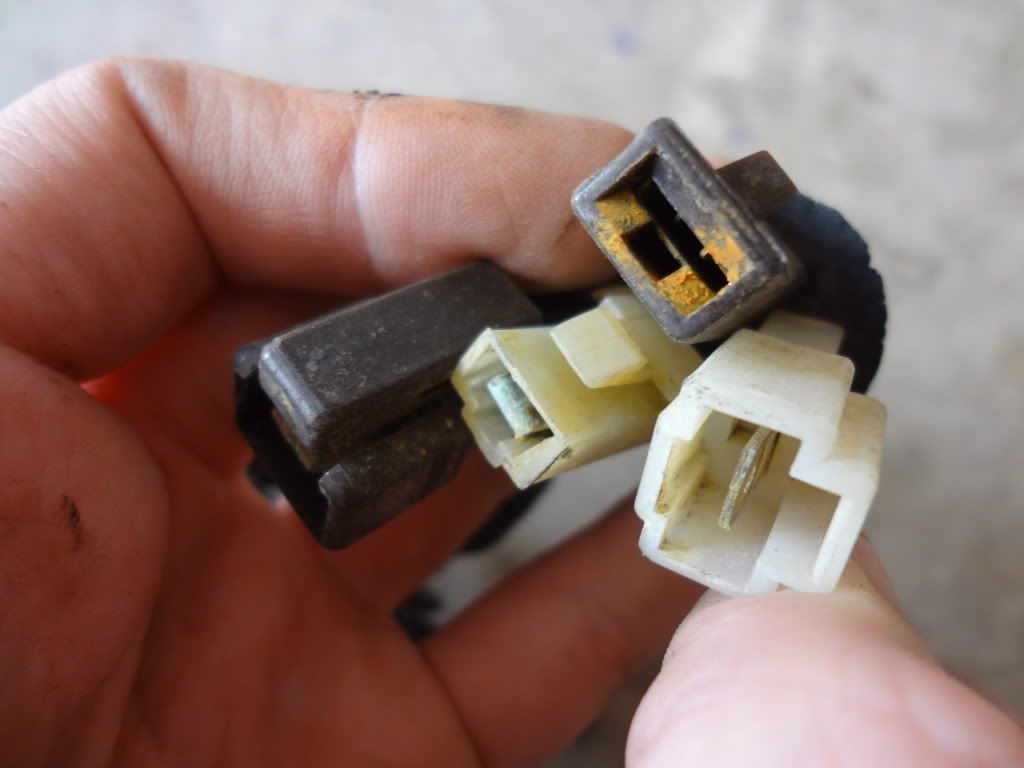

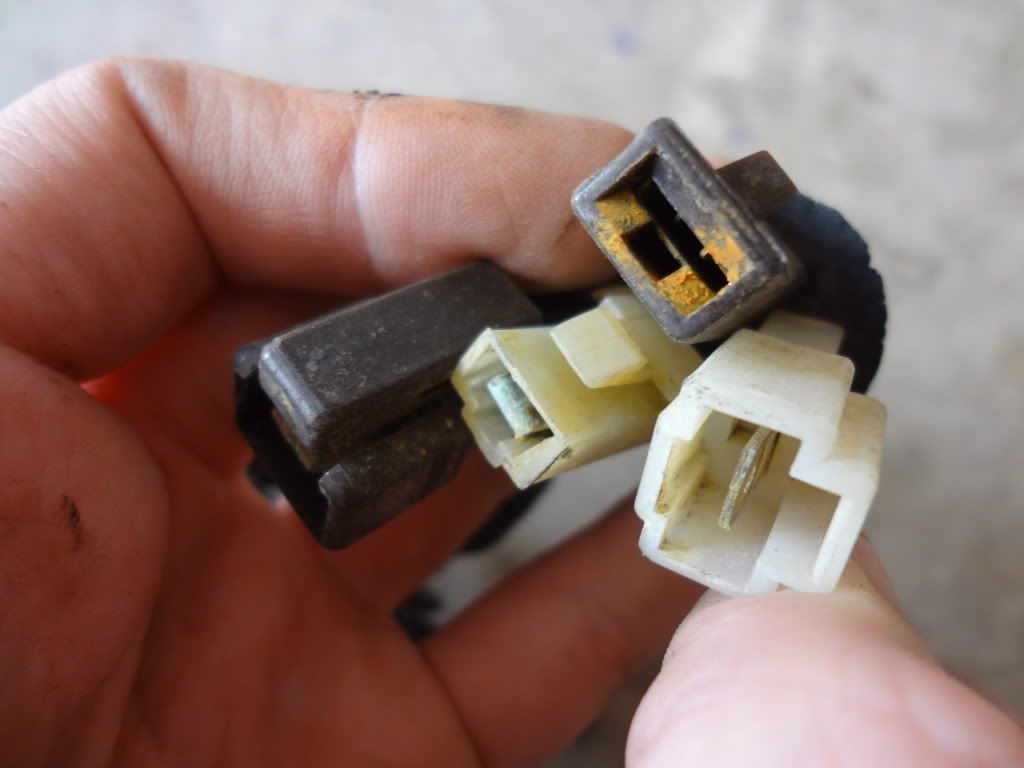

Here's what I'm dealing with.

Here are some pictures of the motors in question. Having them re coating will not be a problem along with powder coating/painting them. It's just the over all condition and the corrosion has just taken its toll on the poor guys.

Here are some pictures of the motors in question. Having them re coating will not be a problem along with powder coating/painting them. It's just the over all condition and the corrosion has just taken its toll on the poor guys.

#7

Sorry for the really big pictures guys.

I didn't know they were going to be that big.

Well the resolution really does it some justice and you can get a really good pictures of what I'm tackling.

Thanks for you input.

I didn't know they were going to be that big.

Well the resolution really does it some justice and you can get a really good pictures of what I'm tackling.

Thanks for you input.

Trending Topics

#8

Looks like they are coroded some. I use Soda blast on electrical components. Its really easy on plastic and delicate parts and would make those connectors look like new again. Mine are more of a cosmedic overhaul as opposed to a mechanical one. You can rebuild the motors with new brushes and cleaning the amatures and such, but its kind of a waste. They aren't really subject to a heavy duty or prolonged load. As long as your wiring and connectors are in good shape, the electrical things should be reliable.

I had the bits re-zinc'd at a local plating shop. Add in the blasting and re painting and you can get similiar results. Some RTV or black silicone in the cracked rubber covers will help seal out crud and moisture too.

I had the bits re-zinc'd at a local plating shop. Add in the blasting and re painting and you can get similiar results. Some RTV or black silicone in the cracked rubber covers will help seal out crud and moisture too.

#9

I appreciate you input Banzai.

What you see if how I received them with dirt and all, in the third picture I rubbed it with a paper tower on the ball joint and was able to get some shine back.

I'll take all the bits and pieces off and see how bad it's actually corroded or just super caked on dirt.

I'll also dig around my garage and see if I can find my original headlight motor.

What is the best way to clean the electrical connectors?

What you see if how I received them with dirt and all, in the third picture I rubbed it with a paper tower on the ball joint and was able to get some shine back.

I'll take all the bits and pieces off and see how bad it's actually corroded or just super caked on dirt.

I'll also dig around my garage and see if I can find my original headlight motor.

What is the best way to clean the electrical connectors?

#10

OR:

buy some better/less beat-up ones!!!!! There are a zillion sets out there and many are bound to be better starting points than yours are. Those are _seriously_ beat up!

Warning: Banzai _always_ makes his rotary art look easy

Not sure I would totally take the word of a guy who has a hand grenade on his work bench...

!!

Stu Aull

80GS

Alaska

buy some better/less beat-up ones!!!!! There are a zillion sets out there and many are bound to be better starting points than yours are. Those are _seriously_ beat up!

Warning: Banzai _always_ makes his rotary art look easy

Not sure I would totally take the word of a guy who has a hand grenade on his work bench...

!!

Stu Aull

80GS

Alaska

#11

Our frozen friend from the tundra makes a sensible point. Sometimes it pays to be more picky when buying parts. And sometimes you get the horn no matter how careful you are. One time, I bought a pair of headlight motors along with several other parts from a fourm member. What I actually got was a single armature winding? A broken bolt had thrawarted their efforts to remove the motor(s), so I guess it was easier to tear the motor itself apart and send the shaft and winding

Live and learn.....Actually, before taking them all apart, I'd make sure that they function smoothly without any noise or problems. No sense is investing time and money only to find out something internal is amiss. This is going to take more than paper towels and windex. I'm talking about taking things down to bare metal and back again. It don't matter how caked on the dirt is, the point is your removing it all. The best way I found to clean those electrical connectors is to soda blast them (not shot blast). Or, with out a blast cabinet, you could hit them with contact cleaner / WD-40 and a small wire brush, like a bore brush for cleaning gun bores. A emery board (like your grand mother may have used on her nails) is an old trick to get into tight places. Used to use those to file down and re surface ignition points.

One warning here. Once you open Pandora's box and redo one component on your beloved, it will only make the other, un-done things look twice as worse. Before you know it, you'll be up to your eccentric shaft in projects draining your time and wallet. Ask me how I know!