Tial MV-R Wastegate Testing

#1

Tial MV-R Wastegate Testing

Hey everyone.

This all started when I was having problems getting the wastegate springs to operate at the pressure that Tial says they should. (within 2 psi)

So Chuck and I decided to take off the wastegate and bench test the MV-R itself and we got some interesting results that i decided to post. i'm interested to see if anyone has run into something like this before.

enjoy

tial tech support was also contacted on this matter through email

The car is a 1993 that we just installed a GT35R on.

15000 miles on engine/transmission/twin turbos ect...

and target psi is 16.5

open dump pipe

the current vacuum line setup...

brass 90 degree off the bottom greddy elbow, all 1/4" id vacuum line going to a brass T splitting the air between the Manual Boost Controller and the fuel atomization line on the lower intake manifold, then from the MBC to the lower air port on the WG.

both top ports are open to free air,the other air ports are blocked,and the water inlet/outlet ports are not being used.

ok so now that u have the setup im running i can go on to the testing we did.

The problem...

i stated the testing with the 1 bar/14.5 psi spring on the MV-R

-MBC set to full open the entire time during testing

-result: 20+ psi w/ absolutely not opening of the wastegate shown.

checked everything tried different spring

-@ .9 bar/ 13.05 spring

-result: same happened here as before

note i started to bleed exhaust now every time around 24+ psi the lower i went on spring pressure the lower it opened but never below 20 psi.

checked everything tried different spring

-@ .7 bar/ 10.15 psi

-result: WG opened at 18-20 psi

@ this point i figured id jump down to a really low spring judging by my results...

-@ .4 bar/ 5.8 lbs spring.

-result: Here i got 5.8 maybe 6 psi

the pressure your supposed to get.

i figured i was getting inconsistent data for some reason and Chuck and I decided to bench test the WG.

we hooked up the wastegate to a air tank and tried out what the spring rates actually open at while off the car and here are the results...

His gauge is within 1/2% accuracy

psi at witch the WG opened at are the posted values

Rated Bar/PSI-----street test psi------bench test psi-----Spring color

.4/5.8--------------------5.8----------------------8-----------------Maroon

.5/7.25-------------------9------------------------------------------Brown, Gold

.7/10.15-----------------12----------------------13----------------Grey, Gold

1/14.5--------------------20+--------------------18.5-------------Brown, Maroon, Grey

remember the exhaust helps push the gate open while on the car so account for that when reading the results

im currently running the .7/10.15psi spring and getting 12 psi witch can be easily turned up to my target of 16.5.

*Note that Chuck and i noticed a small air leaking noise coming from the valve rod from the lower air chamber at .7/10.15 and 1/14.5 psi @ around 9psi i would come and go. We wrote this off as being very minimal and once the metal heated up and expanded it would go away.

Special thanks to Chuck Westbrook!

Also some reference pictures are posted below VVV

This all started when I was having problems getting the wastegate springs to operate at the pressure that Tial says they should. (within 2 psi)

So Chuck and I decided to take off the wastegate and bench test the MV-R itself and we got some interesting results that i decided to post. i'm interested to see if anyone has run into something like this before.

enjoy

tial tech support was also contacted on this matter through email

The car is a 1993 that we just installed a GT35R on.

15000 miles on engine/transmission/twin turbos ect...

and target psi is 16.5

open dump pipe

the current vacuum line setup...

brass 90 degree off the bottom greddy elbow, all 1/4" id vacuum line going to a brass T splitting the air between the Manual Boost Controller and the fuel atomization line on the lower intake manifold, then from the MBC to the lower air port on the WG.

both top ports are open to free air,the other air ports are blocked,and the water inlet/outlet ports are not being used.

ok so now that u have the setup im running i can go on to the testing we did.

The problem...

i stated the testing with the 1 bar/14.5 psi spring on the MV-R

-MBC set to full open the entire time during testing

-result: 20+ psi w/ absolutely not opening of the wastegate shown.

checked everything tried different spring

-@ .9 bar/ 13.05 spring

-result: same happened here as before

note i started to bleed exhaust now every time around 24+ psi the lower i went on spring pressure the lower it opened but never below 20 psi.

checked everything tried different spring

-@ .7 bar/ 10.15 psi

-result: WG opened at 18-20 psi

@ this point i figured id jump down to a really low spring judging by my results...

-@ .4 bar/ 5.8 lbs spring.

-result: Here i got 5.8 maybe 6 psi

the pressure your supposed to get.

i figured i was getting inconsistent data for some reason and Chuck and I decided to bench test the WG.

we hooked up the wastegate to a air tank and tried out what the spring rates actually open at while off the car and here are the results...

His gauge is within 1/2% accuracy

psi at witch the WG opened at are the posted values

Rated Bar/PSI-----street test psi------bench test psi-----Spring color

.4/5.8--------------------5.8----------------------8-----------------Maroon

.5/7.25-------------------9------------------------------------------Brown, Gold

.7/10.15-----------------12----------------------13----------------Grey, Gold

1/14.5--------------------20+--------------------18.5-------------Brown, Maroon, Grey

remember the exhaust helps push the gate open while on the car so account for that when reading the results

im currently running the .7/10.15psi spring and getting 12 psi witch can be easily turned up to my target of 16.5.

*Note that Chuck and i noticed a small air leaking noise coming from the valve rod from the lower air chamber at .7/10.15 and 1/14.5 psi @ around 9psi i would come and go. We wrote this off as being very minimal and once the metal heated up and expanded it would go away.

Special thanks to Chuck Westbrook!

Also some reference pictures are posted below VVV

#5

What happens when you run a single hose directly from the compressor housing to one of the bottom ports on the gate? That's what the instructions say (in your attached image) to do in order to run on spring pressure only.

With an MBC, getting a pressure source from the elbow is more likely to make the gate open later due to the pressure drop across the intercooler. It is the opposite with an EBC connected to the top port on the gate--the pressure drop reduces the amount of air pushing down on the diaphragm, reducing the tendency to spike.

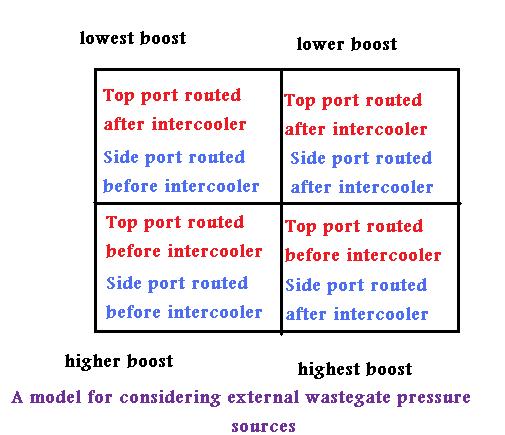

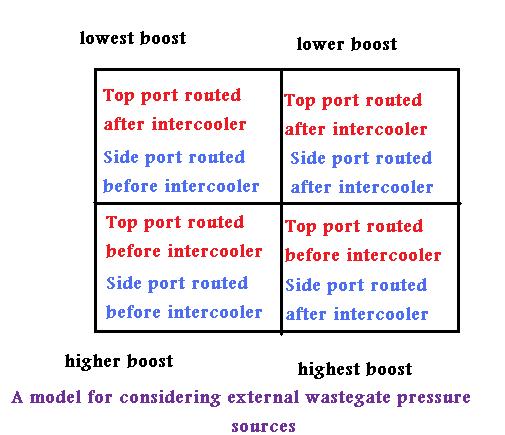

Take a look at this chart I put together a long time ago...

This is for external wastegates using an EBC connected to the top port of the gate. It shows how the pressure differences work. Here are the basic rules:

-- For a hose running to the bottom/side of an external gate, the closer the source is to the compressor housing the earlier the wastegate will open.

-- For a hose running to the top of an external gate, the closer the source is to the compressor housing the later the wastegate will open.

This is true because an external wastegate works on a pressure difference between the top and bottom chambers. Air pressure to the bottom chamber works against spring pressure to open the valve. Air pressure to the top chamber works with the spring pressure to keep the valve shut.

With an MBC, getting a pressure source from the elbow is more likely to make the gate open later due to the pressure drop across the intercooler. It is the opposite with an EBC connected to the top port on the gate--the pressure drop reduces the amount of air pushing down on the diaphragm, reducing the tendency to spike.

Take a look at this chart I put together a long time ago...

This is for external wastegates using an EBC connected to the top port of the gate. It shows how the pressure differences work. Here are the basic rules:

-- For a hose running to the bottom/side of an external gate, the closer the source is to the compressor housing the earlier the wastegate will open.

-- For a hose running to the top of an external gate, the closer the source is to the compressor housing the later the wastegate will open.

This is true because an external wastegate works on a pressure difference between the top and bottom chambers. Air pressure to the bottom chamber works against spring pressure to open the valve. Air pressure to the top chamber works with the spring pressure to keep the valve shut.

#6

rest assured that this among many other thing were all tried in an effort to eliminate all the variables. O and, nothing changed with a direct hose to the gate.

With an MBC, getting a pressure source from the elbow is more likely to make the gate open later due to the pressure drop across the intercooler. It is the opposite with an EBC connected to the top port on the gate--the pressure drop reduces the amount of air pushing down on the diaphragm, reducing the tendency to spike.

-- For a hose running to the bottom/side of an external gate, the closer the source is to the compressor housing the earlier the wastegate will open.

-- For a hose running to the top of an external gate, the closer the source is to the compressor housing the later the wastegate will open.

This is true because an external wastegate works on a pressure difference between the top and bottom chambers. Air pressure to the bottom chamber works against spring pressure to open the valve. Air pressure to the top chamber works with the spring pressure to keep the valve shut.

-- For a hose running to the top of an external gate, the closer the source is to the compressor housing the later the wastegate will open.

This is true because an external wastegate works on a pressure difference between the top and bottom chambers. Air pressure to the bottom chamber works against spring pressure to open the valve. Air pressure to the top chamber works with the spring pressure to keep the valve shut.

the wastegate was off the car connected dirrectly to a air tank. we slowely raised the pressure till the valve moved. thats all

thanks for you input

#7

me and chuck check alot of variables.

even u said yourself that yours ran lower psi then the rated spring rate witch seems more reasonable. u could attribute that to having more then usual back pressure then tial expected and the extra exhaust is helping the spring open earlier. but that just one reason

but in my case im getting pressures that are at sometimes 8+ psi over rated spring pressure.

and the data is supported over multiple spring combinations.

thanks for your input also

Last edited by zman600; 10-20-11 at 08:55 AM.

Trending Topics

#8

When you plugged off the two of the bottom ports on the gate, what did you use to seal the threads? When you are pressurizing it on the bench, spray soapy water around to see if there are any leaks. That can help find problems better than just listening and feeling around. The gate may have a vent built in somewhere (a leak by design), but it could also have damage or defect somehow.

#9

When you plugged off the two of the bottom ports on the gate, what did you use to seal the threads? When you are pressurizing it on the bench, spray soapy water around to see if there are any leaks. That can help find problems better than just listening and feeling around. The gate may have a vent built in somewhere (a leak by design), but it could also have damage or defect somehow.

lol jk

used a thread sealer and never found any leaks.

on a further note the "plugs" never leaked before i applied the sealer too. i put it on anyways of coarse.

#11

#12

I'll bet you a $100 that it's your manifold and not the wastegate springs. I bet I could even tell you what company built your manifold cause I had a customer with the SAME problem. It's not the wastegates or the springs... IME

#13

^would you be more specific.

tell us the reasons the manifold was bad?

what that company your talking about?

is it problem you had applicable? because my manifold is of very good quality

tell us the reasons the manifold was bad?

what that company your talking about?

is it problem you had applicable? because my manifold is of very good quality

Last edited by zman600; 10-20-11 at 10:42 AM.

#14

My WG is the Tial F46.

My GT35R exhaust manifold is from A-Spec.

The WG was tested with the pressure souce coming from both before and after the IC. In both cases with the 10.153 psi spring, minimum boost was about 11 psi.

I run that for normal driving then bump up to 16.3 psi for max fun.

I ended up using the after IC souce for boost as boost control was best there.

My GT35R exhaust manifold is from A-Spec.

The WG was tested with the pressure souce coming from both before and after the IC. In both cases with the 10.153 psi spring, minimum boost was about 11 psi.

I run that for normal driving then bump up to 16.3 psi for max fun.

I ended up using the after IC souce for boost as boost control was best there.

#16

anyways i agree with you on this.

how is before the intercooler psi(ex.18psi) better to use then what actually goes in the engine(ex.16psi).

if you use before the intercooler line the wastegate sees 18 and the engine/boost gauge sees 16 (numbers are just guesses)

may not matter that much but id rather have all of them the same readings to control it better (ex. both see 16psi)

Last edited by zman600; 10-20-11 at 11:16 AM.

#18

That might slow down boost buildup as the exhaust dumps sooner.

Everything involved has an affect on boost build up, minimum boost, and boost control.

That is why it is BEST to experiment on your engine in order to end up with the BEST boost control system. This also includes testing gain and ratio if your EBC has both like my Blitz has.

Everything involved has an affect on boost build up, minimum boost, and boost control.

That is why it is BEST to experiment on your engine in order to end up with the BEST boost control system. This also includes testing gain and ratio if your EBC has both like my Blitz has.

#19

that might slow down boost buildup as the exhaust dumps sooner.

Everything involved has an affect on boost build up, minimum boost, and boost control.

That is why it is best to experiment on your engine in order to end up with the best boost control system. This also includes testing gain and ratio if your ebc has both like my blitz has.

Everything involved has an affect on boost build up, minimum boost, and boost control.

That is why it is best to experiment on your engine in order to end up with the best boost control system. This also includes testing gain and ratio if your ebc has both like my blitz has.

there's more than one way to do it, just have to optimize everything according to your preferences and your application

Thread

Thread Starter

Forum

Replies

Last Post

Shainiac

Single Turbo RX-7's

12

07-17-19 02:20 PM